Insulation

Cork, due to its cellular structure (honeycombs of trapped air), inherently provides thermal insulation that is both non-conductive but also easy to process and shape. By altering granule and void size(s), different technical merits can be emphasized, not only exacerbating the materials’ R-value (thermal resistance), but when employed via a perforating process, it can shift to be a highly effective acoustic material.

Wall Cavity Insulation

Made in a similar way to conglomerated cork flooring, insulation panels also use cork granules, but they tend to be bigger, which enables larger and more angled voids within it, that allow for trapped air (of added value for its’ thermal properties). These panels can be made with natural granules or autoclaved ones, but the premium ‘interior’ panels tend to use natural cork, which keeps the autoclaved, burnt smell away.

Flooring Underlayment Insulation

Underlayment rolls also rely on the presence of air pockets created by lowering the compression density (when compared to the density to make durable flooring), and unlike flooring compression, the underlayment roll material is made in large cylinders. Once compressed and cured, the material is cut to the desired thickness via a rotary cutting machine. Thicknesses rage from 3mm-8mm.

Ceiling/Wall Insulation Panel

Like the wall cavity insulation referenced above, the interior version of the product can be used as an acoustic insulative material for ceilings and walls. The panels can be used ‘as-is’ cut into slabs from large blocks, or they can be milled (and painted as needed), and be used in a dropped ceiling application.

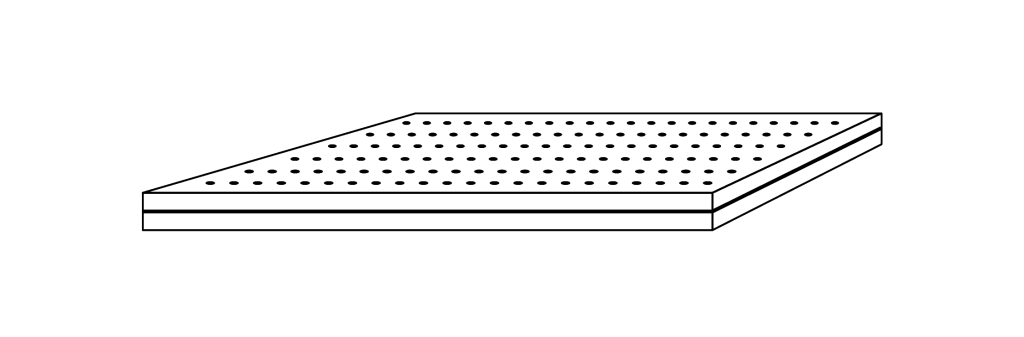

Perforated Molded Acoustic Panels

The custom molded shape manufacturing methodology can also be used to create ‘acoustic’ tiles, which is typically done in a pattern that incorporates holes, slits or grooves in the design. These perforations allow sound to transfer through the design, and either diminish as it bounces around, or can be more greatly absorbed if a highly absorbent material is used behind the decorative facade.