Flooring

Cork flooring provides softness underfoot, high levels of slip resistance, and long-term durability. Product renditions offer differing benefits, that excel in different applications, but with cork, your baseline is ‘sustainability’.

Solid Tile

Solid cork tile flooring is typically made into tiles and come in 2 main variations: granulated solid and granulated solid with veneer. The granulated options are available in bigger sizes due to the fact that the can be made into sheets (ie: combining granules).

Laminated Plank

Laminated cork flooring planks are typically made by applying a natural cork veneer on to a stable substrate that also has the rigidity to allow for the milling of a joining/locking system (like Tongue and Groove). Over the last several decades the substrate of choice for manufacturers has been high-density fiberboard (HDF), though more recently, new substrates focusing on durability and carbon neutrality have been developed.

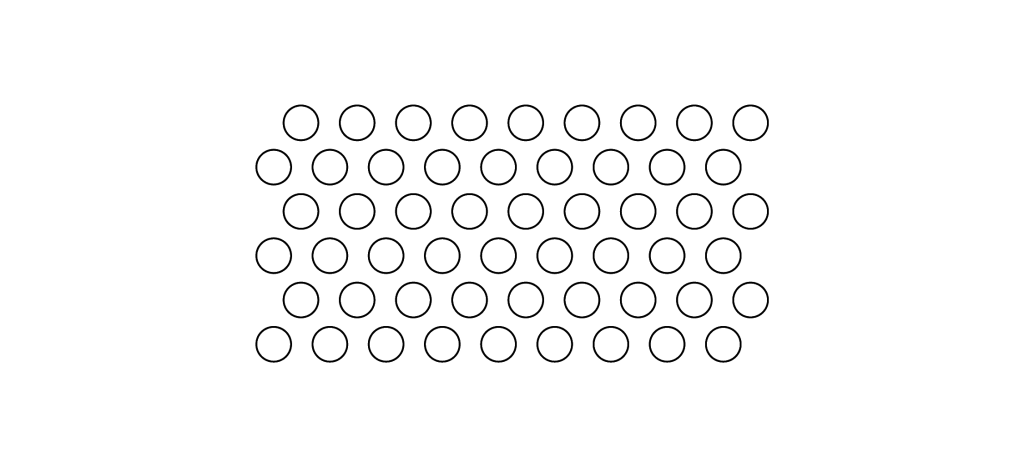

Mosaic Cork Disc Sheet

The Cork Mosaic tile uses unaltered natural cork (ie: no glue), taken as a byproduct from cork stopper production. Cork stoppers not used in the bottling industry (typically because they have too many voids and are not high enough quality), are sliced in ¼” discs, and then applied to a mosaic sheet backer (like those used for cementitious tile mosaics). This material is typically glued down, and grouted.